Wittmann-Battenfeld: https://www.wittmann-group.com/de_at/imd-iml-technologie-zur-herstellung-dekorierter-funktionalisierter-oberflaechen

OM-Online: https://www.om-online.de/wirtschaft/produktionsidee-aus-steinfeld-soll-den-weltmarkt-aufrollen-89301

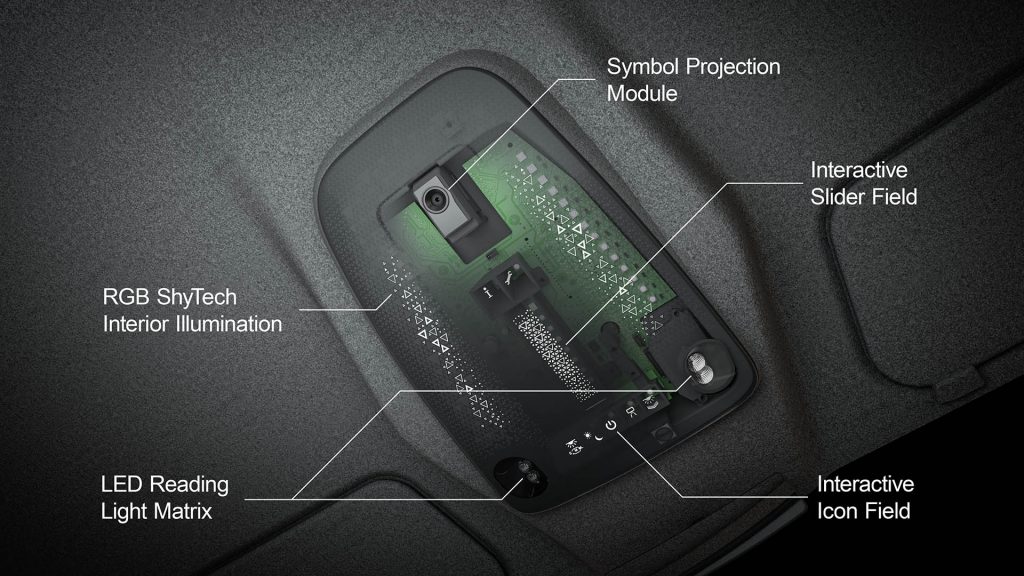

K-Zeitung: https://www.k-zeitung.de/pkw-innenbeleuchtung-ein-teil-aus-der-spritzgiessmaschine/

Plastikverarbeiter: https://www.plastverarbeiter.de/automation/syntech-plastics-staerkt-seine-kompetenzen-in-der-entwicklung-und-produktion-von-dekorativen-und-funktionalisierten-oberflaechen-618.html

Plasticker: https://plasticker.de/news/shownews.php?nr=40111&tmp=1634680068

Elektroniknet: https://www.elektroniknet.de/automotive/infotainment/kfz-innenraum-interaktiv-gestalten.190866.html